In a significant leap forward for pharmaceuticals, researchers at the University of Nottingham’s Centre for Additive Manufacturing, in collaboration with the School of Pharmacy, have pioneered a groundbreaking technique for 3D printing medication. This innovative method allows for the creation of personalized pills capable of delivering multiple drugs in a single tablet while ensuring timed doses, potentially transforming the landscape of drug delivery.

Published in Materials Today Advances, the research unveils the capabilities of Multi-Material InkJet 3D Printing (MM-IJ3DP) in fabricating tailored pharmaceutical tablets with precisely controlled drug release profiles. By leveraging this cutting-edge technology, tablets can be engineered to release drugs at predetermined rates, dictated by the tablet’s intricate design. Central to this technique is a novel ink formulation comprising molecules sensitive to ultraviolet light, which, upon printing, assemble into a water-soluble structure.

Dr. Yinfeng He, Assistant Professor at the Centre for Additive Manufacturing, expressed enthusiasm about the implications of this advancement, stating, “This is an exciting step forwards in the development of personalized medication.” He underscored the potential of 3D printing to revolutionize drug delivery and emphasized the newfound possibilities for next-generation personalized medicines.

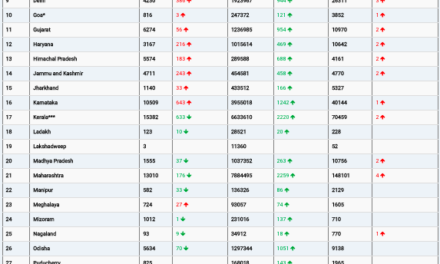

The versatility of MM-IJ3DP allows for the incorporation of multiple drugs into a single tablet, simplifying complex medication regimens into a unified dose. Professor Ricky Wildman highlighted the technology’s scalability, noting its capability to produce 56 pills in a single batch. However, challenges persist, including the necessity for formulations supporting a broader range of materials. Ongoing research aims to address these hurdles, enhancing the feasibility of MM-IJ3DP for widespread application.

According to Professor Felicity Rose from the School of Pharmacy, who co-authored the research, personalized medication represents the future of pharmaceutical care. With up to 50% of individuals in the UK alone failing to adhere to their prescribed medication regimens, the potential impact of personalized pills is substantial. Simplifying complex medication schedules into a single pill could significantly improve adherence and health outcomes for patients managing multiple conditions.

The implications of this breakthrough extend beyond convenience; the technology holds promise for diseases requiring precise timing and dosage accuracy. By offering tailored drug release profiles, personalized pills could optimize treatment efficacy and patient outcomes.

As the research continues to evolve, the prospect of personalized medication becoming a cornerstone of pharmaceutical practice grows increasingly tangible. With further refinement, Multi-Material InkJet 3D Printing is poised to reshape drug delivery, ushering in a new era of precision medicine tailored to individual needs.