Integration of 3D printing and pharmaceuticals has resulted in a novel type of mask which attacks the virus when viral particles come in contact with it. Developed by Pune-based start-up firm Thincr Technologies India Private Limited, these masks are coated with anti-viral agents known otherwise as virucides. The virucidal mask project is among the earliest projects to have been selected for commercialization, by the Technology Development Board (TDB), a statutory body of the Department of Science and Technology, Government of India, as part of the Government’s fight against COVID-19.

The project received financial support from TDB as part of its search for novel solutions to fight COVID-19, in May 2020. Following this, an agreement was signed on 8th July, 2020 for developing the masks. The 2016-incorporated firm claims that these cost-effective masks are more effective in checking the spread of COVID-19, in comparison with ordinary N-95, 3-ply and cloth masks.

Addressing the Need for High Quality More Effective Masks

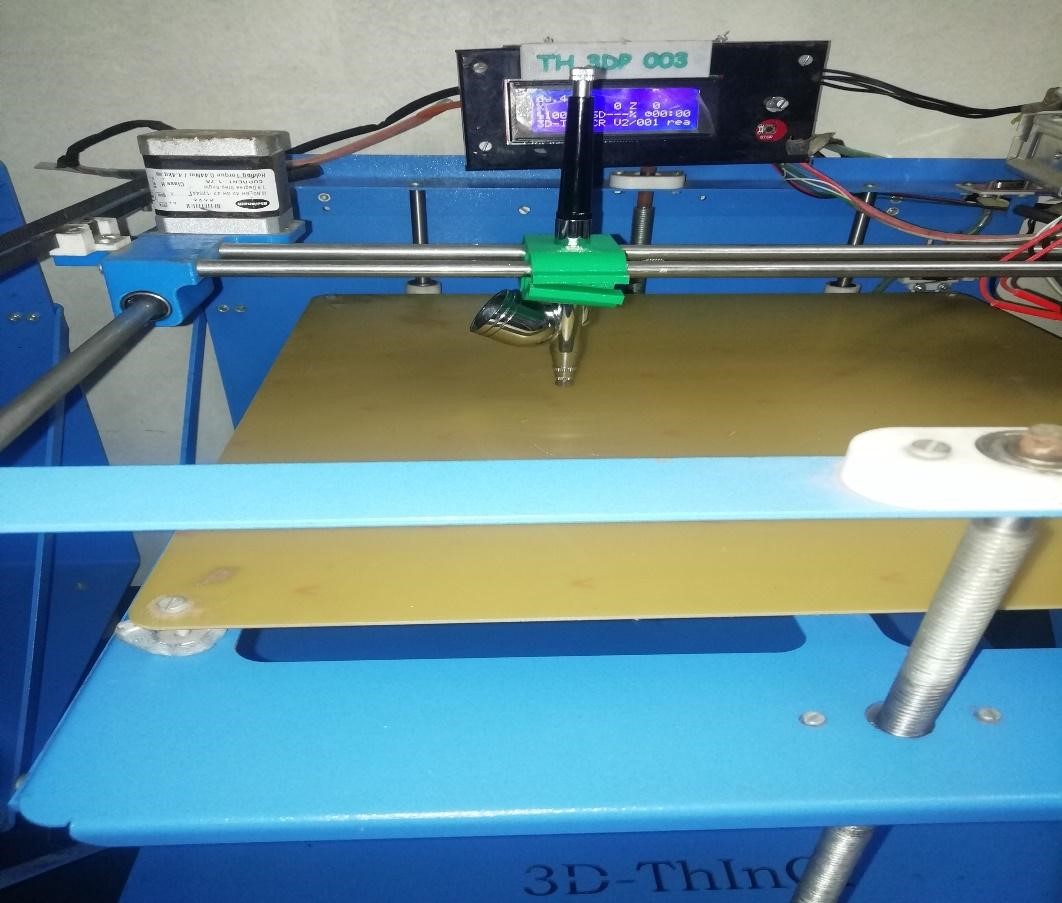

Thincr Technologies India works in development of Fused Deposition Modeling (FDM) 3D-printers to discover new pharmaceutical formulations and drug-loaded filaments of different drugs. Founder Director Dr. Shitalkumar Zambad explains: “We started thinking of the problem and possible solutions, during the initial days of the pandemic. We sensed that use of face masks will become nearly universal as the most important tool to prevent infection. But we realized that most masks which were then available and within the reach of common people were homemade and of relatively low quality. It is this need for high-quality masks which led us to undertake a project to develop and commercialize cost-effective and more efficient virucidal coated masks, as a better approach to reduce the spread of infection”.

The Development Journey

With this aim, Thincr Technologies began to focus on developing virucidal coating formulations. It was developed with support from Merck Life Sciences located in Nerul, whose research facility was used for the purpose. The coating formulation has been utilized to coat the fabric layer and the 3D printing principle was employed to achieve uniformity of coating. The coated layer can be incorporated as an additional layer in N-95 masks, 3-Ply masks, simple cloth masks, 3D printed or other plastic cover masks, along with reusable filters. These masks thus provide an additional protection beyond the protection achieved by filtration mechanisms.

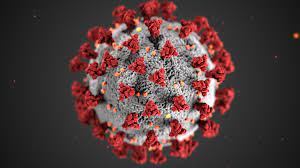

The coating has been tested and shown to inactivate the SARS-COV-2 virus. The material used for coating on the mask is a Sodium Olefin Sulfonate based mixture. It is a soap forming agent with hydrophilic and hydrophobic properties. In contact with enveloped viruses, it disrupts the outer membrane of the virus. The ingredients used are stable at room temperature and are widely used in cosmetics.

The filters of these reusable masks have also been developed using 3D printing. Further, Dr. Zambad says that the masks have been found to have bacterial filtration efficiency higher than 95%. “In this project, for the first time, we used 3D-printers to make multilayer cloth filters to precisely fit for plastic-moulded or 3D-printed mask covers”.

Thincr Technologies India Pvt. Ltd. has applied for a patent for this product. Commercial scale manufacturing has also started, informs Dr. Zambad. Meanwhile, 6,000 virucidal masks have been distributed by an NGO to four Government Hospitals in Nandurbar, Nashik and Bengaluru, for use by healthcare workers and also to a girls’ school and college in Bengaluru.

***

DJM/Sriyanka/DY/PIB Mumbai