Innovative Microlenses Offer New Hope for Myopia Management

A groundbreaking laser technique developed by the Fraunhofer Institute for Microstructure of Materials and Systems IMWS is poised to revolutionize the treatment of nearsightedness (myopia). The newly devised method, known as laser swelling, facilitates the production of microlenses that can be integrated into eyeglasses, potentially mitigating the long-term risks associated with myopia, such as retinal detachment, cataracts, and macular degeneration.

Addressing a Growing Global Concern

Recent studies indicate that approximately 33% of children and youth over the age of five are currently affected by myopia, with projections suggesting an increase of seven percentage points by 2050. This would result in over 740 million children facing a heightened risk of severe vision impairments.

To counteract this growing concern, researchers have developed microlenses that are incorporated into specialized eyeglasses designed to slow the elongation of the eyeball—a key factor in myopia progression. These lenses employ a superimposed focal point on the periphery, effectively reducing the eye’s tendency to grow longer and exacerbating nearsightedness.

The Breakthrough: Laser Swelling Technology

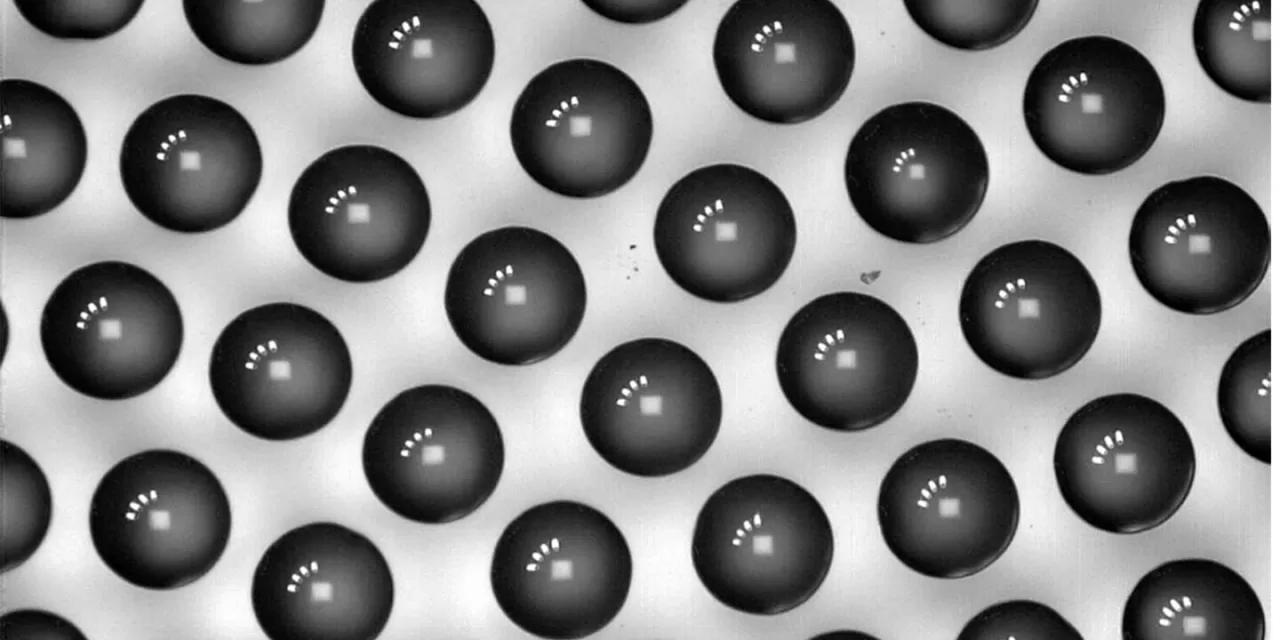

The innovative laser swelling method allows for the precise and cost-effective creation of microlenses. The process involves directing an infrared laser onto polymers used in eyeglass manufacturing. The laser heats the material, prompting internal water molecules to generate localized pressure, forming a microscopic protrusion—a microlens or lenslet.

“The laser beam can be positioned with great accuracy on surfaces, enabling the production of significantly smaller microlenses than previously possible,” stated Prof. Thomas Höche, the lead researcher behind the technology. “This flexibility allows for the customization of eyeglasses tailored to individual needs.”

Unlike traditional injection molding, which is labor-intensive and requires extensive cleaning and maintenance, laser swelling is a contact-free, environmentally friendly alternative that does not generate microplastics. Furthermore, the technique allows for the fabrication of lenses in a variety of shapes, including spherical, aspheric, and cylindrical forms, expanding its potential applications.

Expanding Applications Beyond Eyeglasses

Beyond its use in eyeglass manufacturing, laser swelling technology holds promise for a range of applications, including intraocular lenses, microfluidic components, compact microscopes, and even medical product labeling. The ability to imprint discreet tracking codes on medical supplies, such as syringes, could enhance product authenticity and safety.

The Fraunhofer IMWS team has applied for global intellectual property rights and is actively working towards commercializing this innovative technology. “Our primary focus remains on the eyeglass market, aiming to create customized corrective eyewear tailored to specific professional and medical needs,” Höche affirmed.

Disclaimer

This article is based on research findings and advancements shared by the Fraunhofer-Gesellschaft. The information presented here is for informational purposes only and does not constitute medical advice. Individuals with vision concerns should consult an eye care professional for diagnosis and treatment recommendations.