In a recent laboratory study conducted by scientists at the National Institute of Allergy and Infectious Diseases (NIAID), part of the National Institutes of Health, researchers explored the effectiveness of heat treatment on H5N1 influenza virus present in raw milk. The findings, published in the New England Journal of Medicine, highlight significant reductions in infectious virus levels with heat, yet underscore potential challenges for large-scale industrial pasteurization.

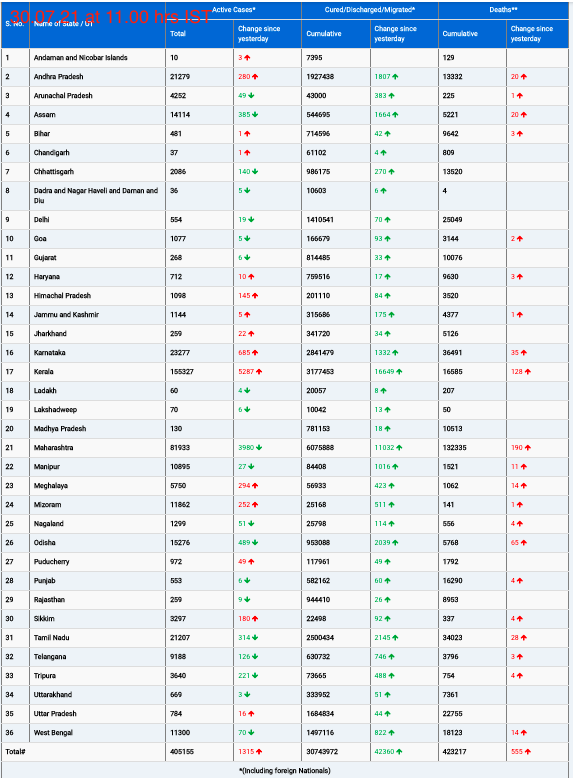

The study comes in response to recent concerns following outbreaks of highly pathogenic avian influenza virus (HPAI H5N1) among dairy cows in the United States. As of late March 2024, 95 cattle herds across 12 states have been affected, with three cases of human infection reported among farm workers. While the virus has not shown evidence of human-to-human transmission, public health officials remain vigilant.

The NIAID researchers, based at Rocky Mountain Laboratories, examined the stability of H5N1 virus in raw milk subjected to temperatures typical of commercial pasteurization processes: 63°C (145.4°F) and 72°C (161.6°F). Using viral isolates obtained from a deceased mountain lion in Montana, the scientists spiked raw milk samples and heated them for various durations at these temperatures.

Their findings revealed that heating at 63°C for just 2.5 minutes led to a substantial decrease (1010-fold) in infectious virus levels. Standard pasteurization protocols, which typically involve 30 minutes at this temperature, effectively eliminate infectious virus. However, at 72°C, while a 104-fold reduction was observed within five seconds, small amounts of infectious virus persisted in some samples after 15 seconds of heat treatment.

“This study underscores the effectiveness of heat in reducing H5N1 virus in raw milk, especially at lower pasteurization temperatures,” the authors noted. However, they cautioned that the persistence of small amounts of infectious virus at higher temperatures and shorter durations highlights potential challenges for industrial processes.

The researchers emphasized that their findings are based on controlled laboratory conditions and do not directly translate to real-world pasteurization processes or safety of the milk supply. They highlighted the need for further studies using infected milk under conditions that mimic commercial pasteurization equipment to better assess safety measures.

The U.S. Food and Drug Administration (FDA), in collaboration with the U.S. Department of Agriculture (USDA), continues to monitor the situation closely. Initial surveys of retail dairy products across multiple states have shown no viable virus in any samples tested, reassuring the safety of the commercial milk supply.

“While laboratory studies are crucial for understanding virus dynamics, replicating these findings in real-world conditions remains essential,” the FDA stated. Ongoing validation studies are underway to refine pasteurization techniques, ensuring the continued safety of dairy products.

As the situation evolves, further updates from regulatory bodies and additional research will provide clarity on mitigating risks associated with avian influenza viruses in dairy products.