Rourkela, India – Researchers at the National Institute of Technology (NIT) Rourkela have announced a groundbreaking eco-friendly method to efficiently remove carcinogenic dyes from industrial wastewater. This innovative approach, revealed on Thursday, combines advanced nanocomposite-based ceramic membranes with microbubble technology, offering a promising solution to persistent water pollution challenges.

The study, supported by the Anusandhan National Research Foundation, addresses a pressing environmental concern. Industrial wastewater, particularly from textile and dye manufacturing sectors, contains harmful dyes like Bismarck Brown R, which pose significant risks due to their carcinogenic properties and resistance to conventional filtration methods.

Advanced Hybrid Technology for Wastewater Treatment

Traditional treatment methods, such as ultraviolet (UV) filtration, often struggle to effectively eliminate dye pollutants at a large scale. To overcome these limitations, the research team at NIT Rourkela devised a novel system integrating two advanced technologies.

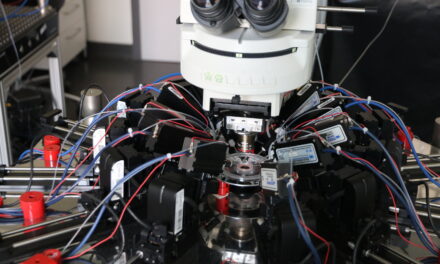

The first component of this hybrid system is a ceramic membrane coated with an industrial-waste-derived Zeolite and Zinc Oxide nanocomposite. This photocatalytic material is designed to break down dye molecules upon exposure to light, significantly enhancing the purification process.

The second component utilizes microbubble technology. A simple air diffuser generates microbubbles that enhance mass transfer, facilitating the breakdown and removal of harmful dyes.

To test this system, the researchers developed a continuous tangential flow membrane photoreactor and evaluated its performance using both simulated and real wastewater samples from a local dyeing facility.

Promising Results and Future Applications

The experimental results showcased remarkable efficiency. According to Prof. Sujit Sen from the Department of Chemical Engineering at NIT Rourkela, the system achieved a 95.4% decolourisation of Bismarck Brown R and a 94% reduction in chemical oxygen demand (COD) within just 90 minutes.

“The nanocomposite functioned effectively under visible light, making this approach highly practical for real-world wastewater treatment applications,” Prof. Sen explained.

The potential impact of this technology extends beyond the textile industry. It offers a sustainable and cost-effective alternative to conventional oxidation methods, which often rely on expensive chemicals and complex machinery. Other industries, such as steel, petrochemicals, and pharmaceuticals, could also benefit from this eco-friendly treatment solution.

The findings of this research have been published in the Journal of Environmental Chemical Engineering, further reinforcing the significance of this innovative approach in addressing global water pollution issues.

Disclaimer: This article is based on research findings and aims to highlight scientific advancements. The effectiveness of the described technology may vary depending on specific industrial applications and environmental conditions.