Innovative Technique Holds Promise for Patients Needing Ear Reconstruction

In a remarkable feat of medical innovation, researchers at Weill Cornell Medicine and Cornell Engineering have achieved a significant milestone in the field of tissue engineering: the creation of a replica of an adult human ear that not only looks but also feels remarkably natural. Utilizing state-of-the-art tissue engineering techniques alongside 3D printing technology, the breakthrough offers new hope for individuals requiring ear reconstruction due to congenital malformations or traumatic loss.

The groundbreaking study, published online in Acta Biomaterialia on March 16, showcases the potential of this pioneering approach to provide grafts with well-defined anatomy and biomechanical properties closely resembling those of a natural ear. Dr. Jason Spector, chief of the Division of Plastic and Reconstructive Surgery at NewYork-Presbyterian/Weill Cornell Medical Center and a professor of surgery (plastic surgery) at Weill Cornell Medicine, underscores the transformative impact of this technology on the field of reconstructive surgery.

“Ear reconstruction requires multiple surgeries and an incredible amount of artistry and finesse,” explains Dr. Spector. “This new technology may eventually provide an option that feels real for thousands needing surgery to correct outer ear deformities.”

Traditionally, ear reconstruction procedures involve harvesting cartilage from a child’s ribs, a process fraught with pain and scarring. While effective in crafting a replacement ear, the resulting graft often lacks the flexibility and natural appearance of the recipient’s other ear. Driven by the need for a more refined solution, researchers turned to tissue engineering and 3D printing to address this challenge.

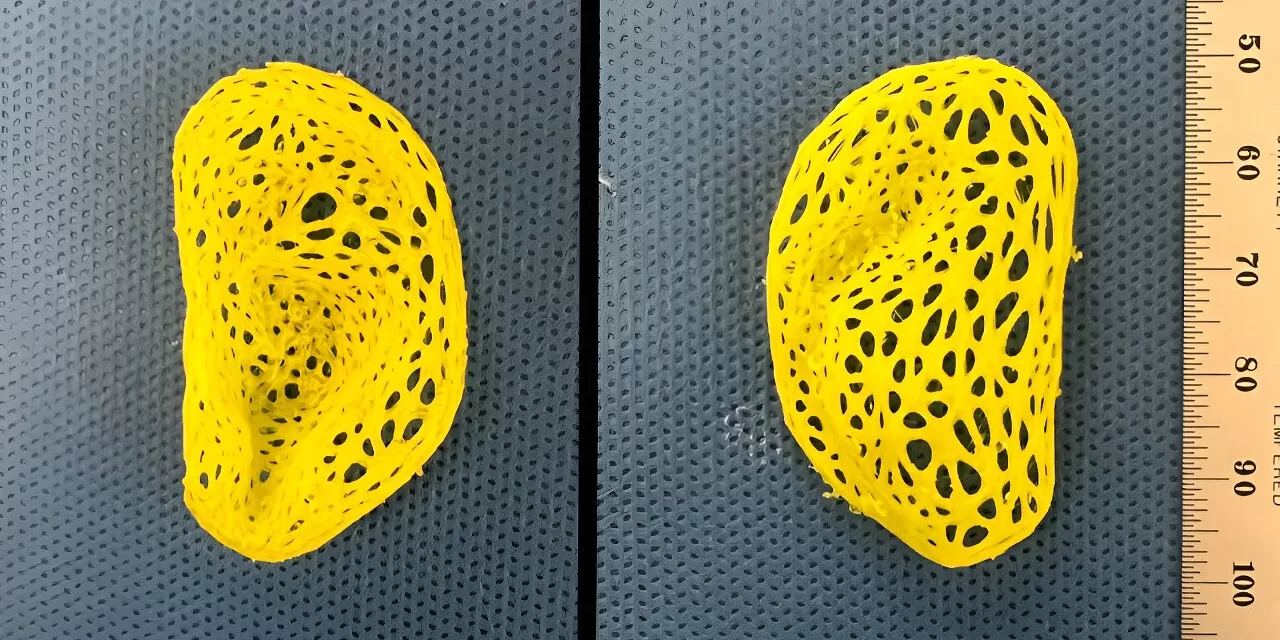

To produce a more lifelike replacement ear, the researchers utilized animal-derived cartilage treated to minimize the risk of immune rejection. This cartilage was then incorporated into intricate, ear-shaped plastic scaffolds created using 3D printing technology, based on precise data obtained from a person’s ear. Acting as internal reinforcements, these cartilage pieces facilitated the formation of new tissue within the scaffold, preserving the ear’s intricate anatomical features and preventing contraction.

Over the course of three to six months, the engineered structure developed into cartilage-containing tissue closely mirroring the characteristics of a natural ear, including its ridges, curves, and whorls. Biomechanical studies, conducted in collaboration with engineering expert Dr. Larry Bonassar from Cornell University, confirmed that the replicas exhibited flexibility and elasticity comparable to human ear cartilage, marking a significant advancement in tissue engineering.

While the engineered material demonstrated remarkable similarities to natural cartilage, it exhibited slightly reduced strength and was prone to tearing. Dr. Spector plans to address this limitation by incorporating chondrocytes derived from the recipient’s own cartilage, enhancing the graft’s biomechanical properties and further refining its resemblance to the native ear.

As the research continues to progress, the potential applications of this groundbreaking technology in reconstructive surgery are vast, offering renewed hope and improved outcomes for individuals requiring ear reconstruction. With further advancements on the horizon, the collaboration between medicine and engineering stands poised to revolutionize the field of tissue engineering and enhance the quality of care for patients worldwide.